Conduction Cooled Systems

Conduction Cooled Systems

Custom design of each system based on common approaches of appropriate standard, used for rugged flexible solutions (IP65-67), allows using high performance modules in systems that maintain reliability at high operating temperatures (up to 70ºC).

COM Express PC/104-plus StackPC-PCI CPCI Serial

Target application

|

-40/+70 ºС

|

|

EN50155, EN60068

|

|

10/100/150g Vibration/Shock

|

|

EN61373

|

|

|

IP65-67, IK08-IK10

|

|

IEC60529, EN62262

|

|

Salt mist

|

|

EN60068

|

|

Damp Heat

|

|

EN60068

|

|

|

EMC

(Electromagnetic compatibility)

|

|

IEC61000

|

Choose your form factor

COMPACT PCI

SERIAL

|

STACKABLE PC

StackPC

|

|

|

PICMG CPCI-S Standard

picmg.org

|

StackPC Standard

www.stackpc.org

|

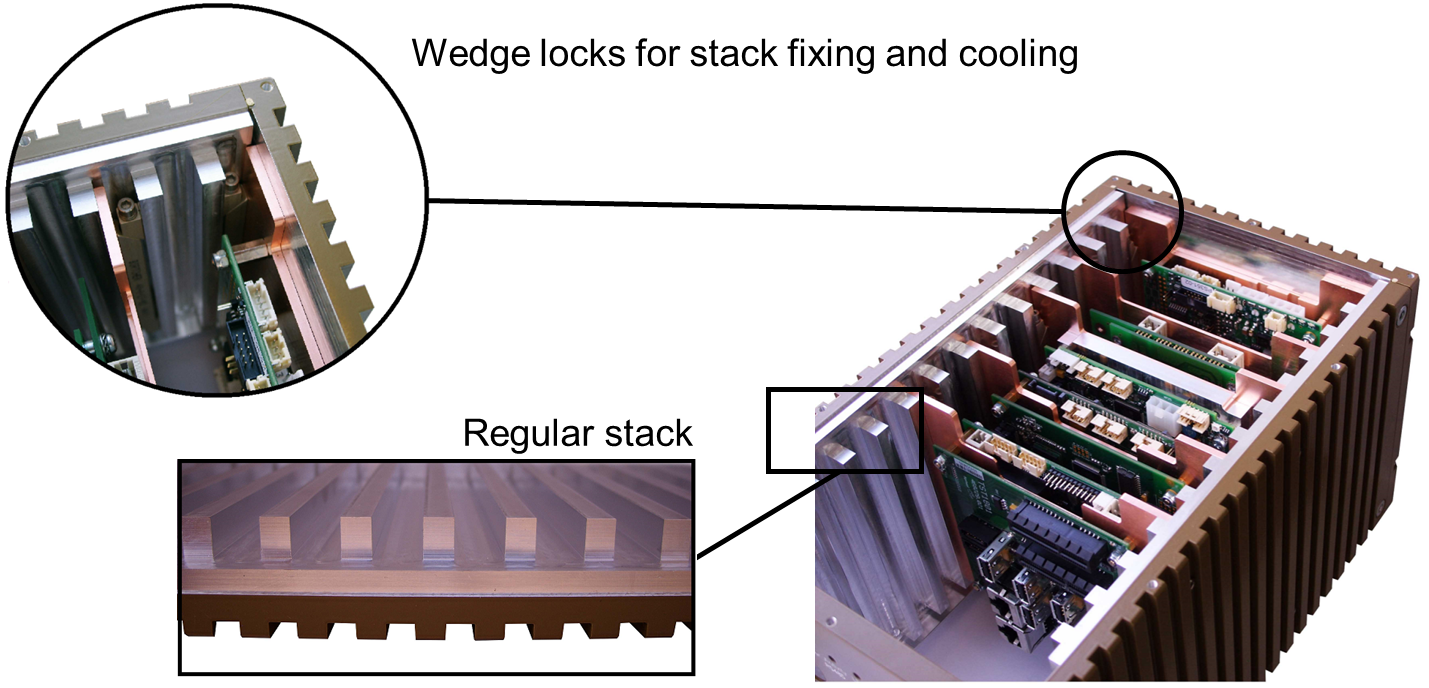

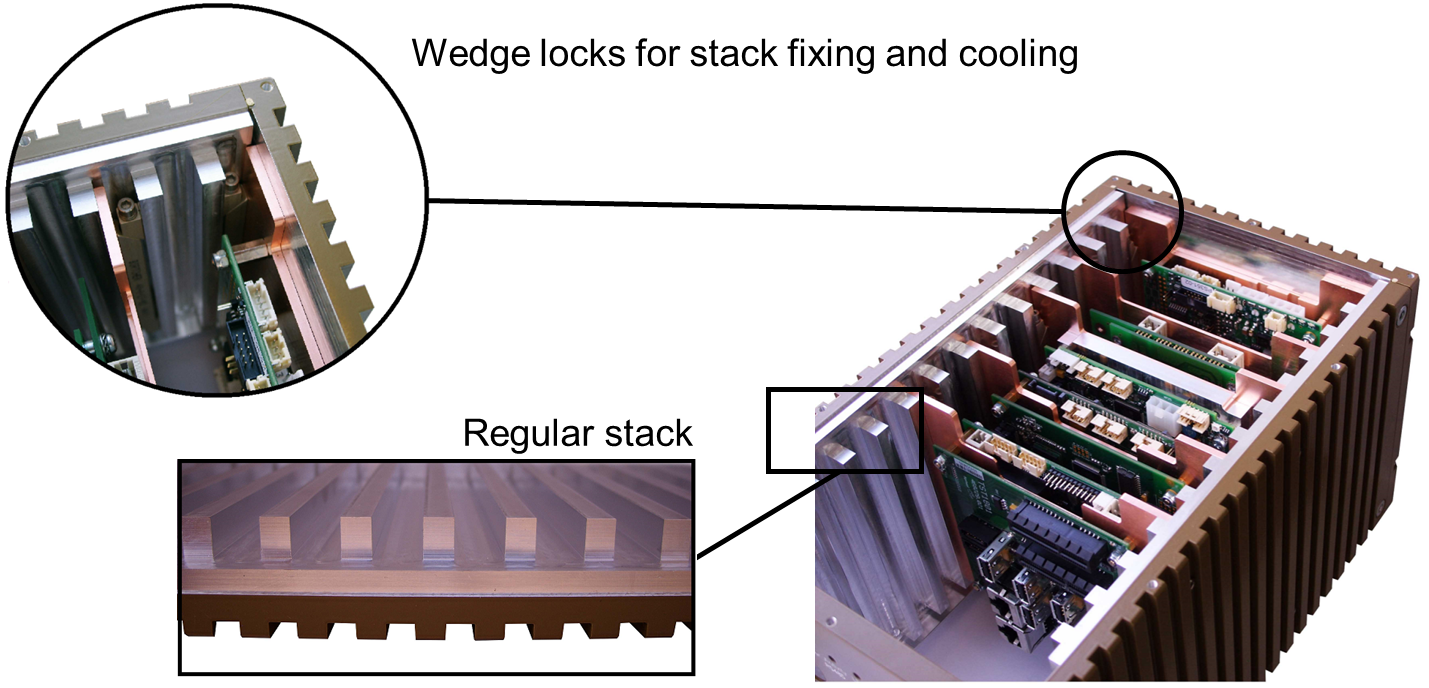

CPCIs PICMG

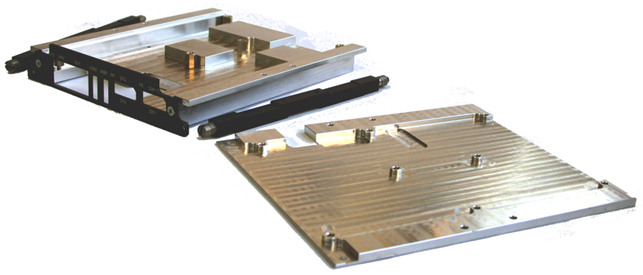

Conduction Cooled Assembly (CCA)

|

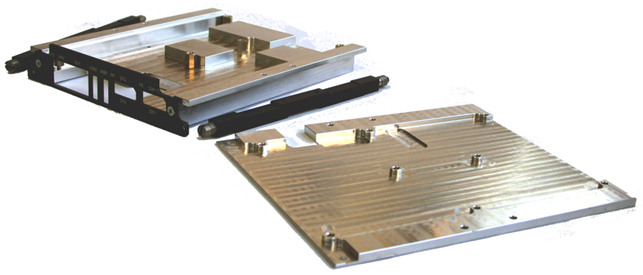

CCA FRAME (1st Part of CCA assembly)

- Front board cassette dimensions which cover PCB

- Card retainer (Wedge Locks)

- Ejectors

- Board pitch 5HP

|

CCA ENCLOSURE (2nd Part of CCA assembly)

- Card retainer channel width

- Backplane position

- Board Pitch 5HP

|

|

|

CCA Enclosure

Enclosure surface works as system heatspreader

CCA frame surface works as module heatspreader

CCA ENCLOSURE DEFINES:

- Card retainer channel width

- Backplane position

- Board pitch 5HP

- Usually custom design according to customer system requirements

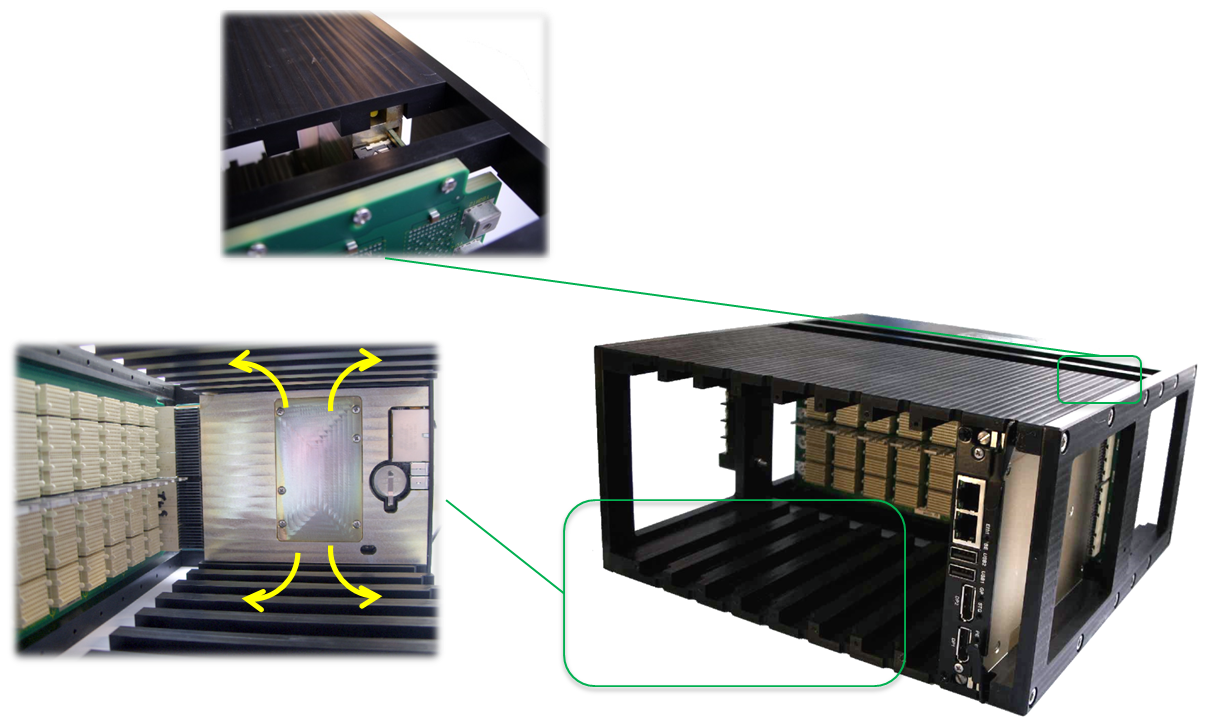

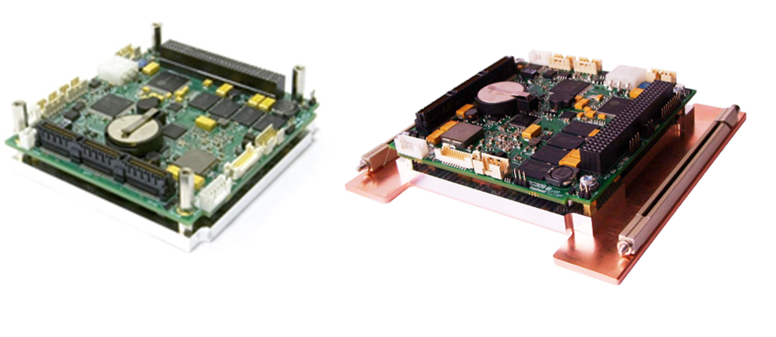

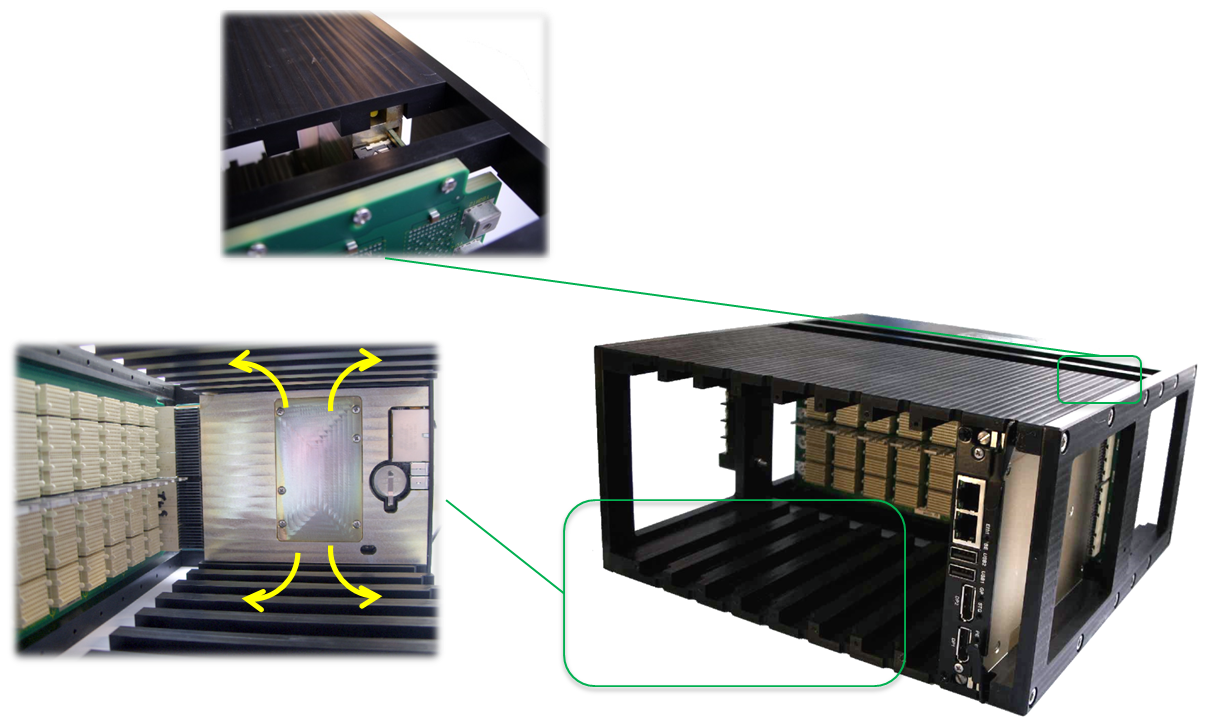

CPCI-Serial Modules

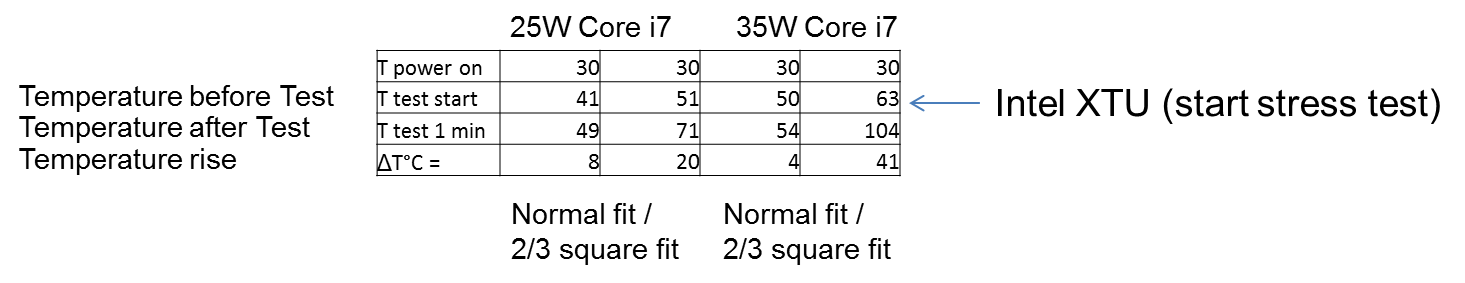

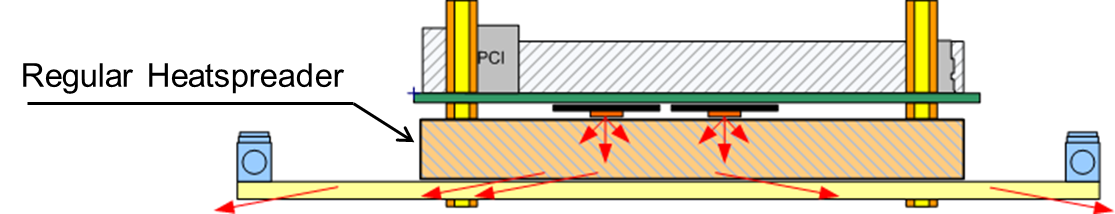

Each CPCI module has one or few hot components that should fit CCA frame

Main idea is to dissipate power along the frame to it’s edges

Main difficulty to provide good cooling solution is chips tolerances

Each chip has it’s surface roughness and flatness

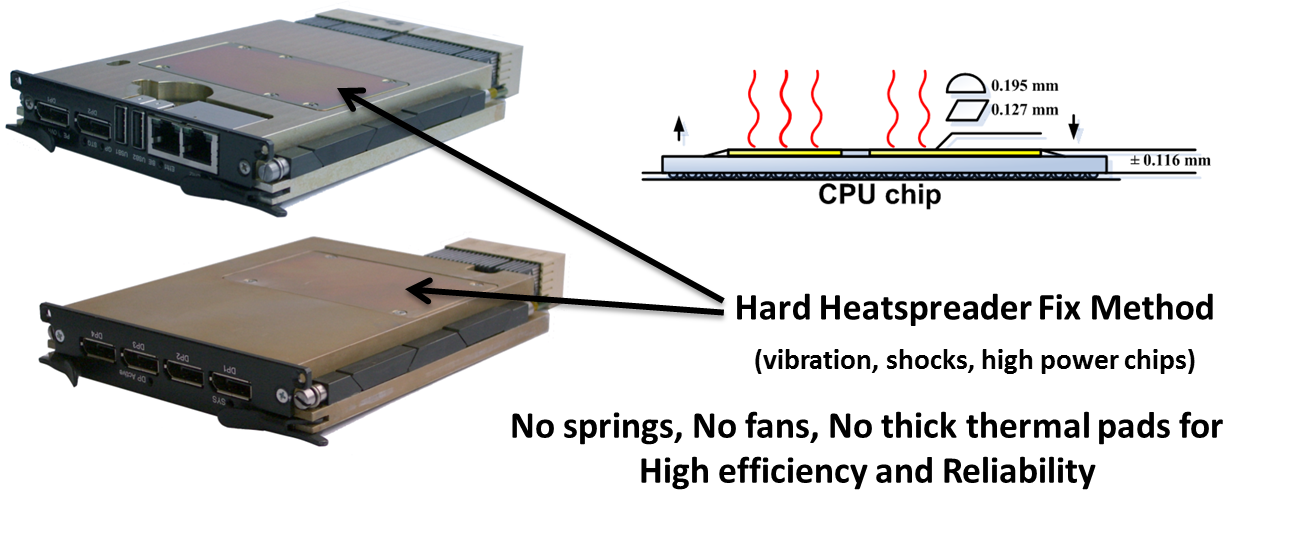

Fastwel modules has adjustable heatspreader part with heat pipes inside for high performance modules

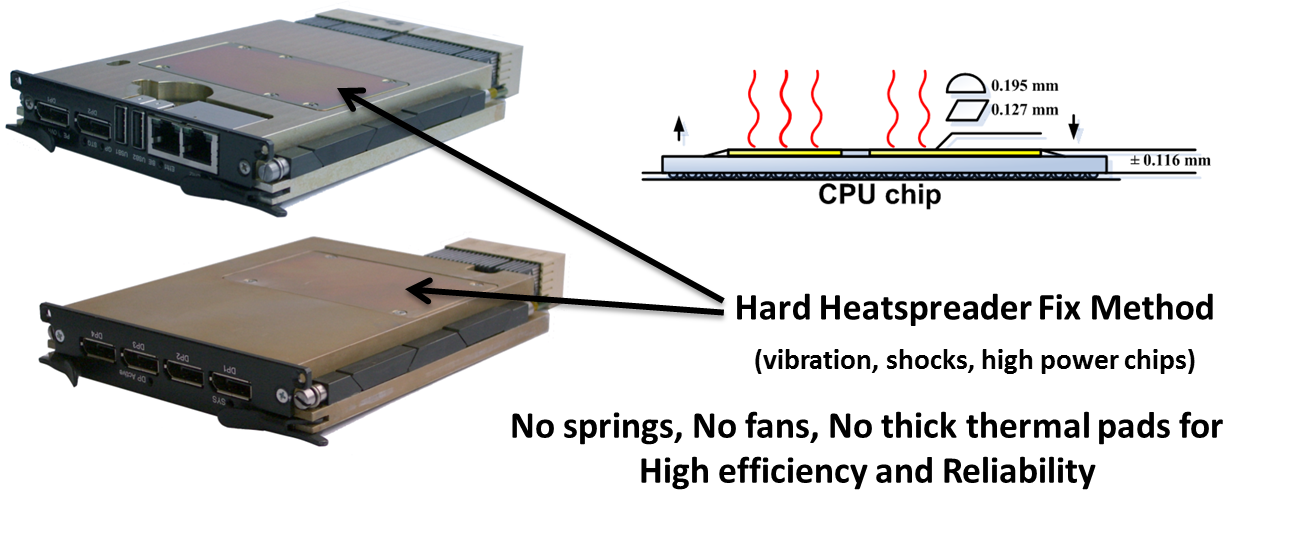

Heat Dissipation Model

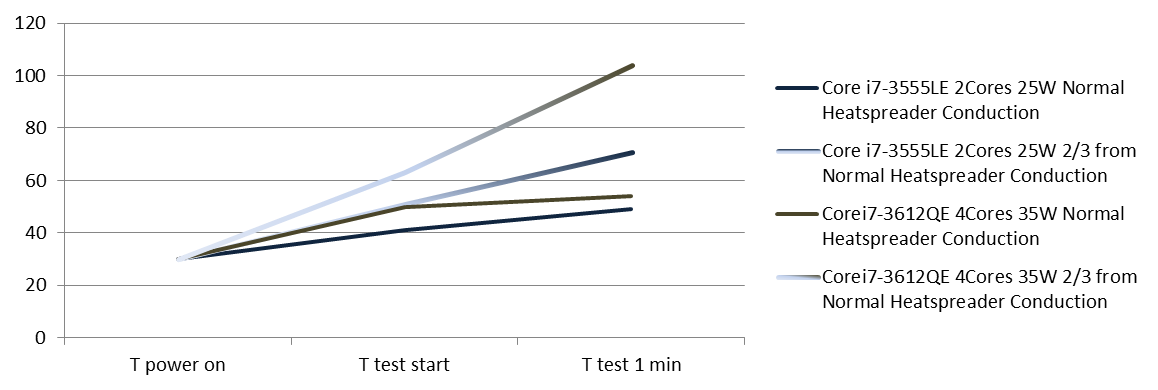

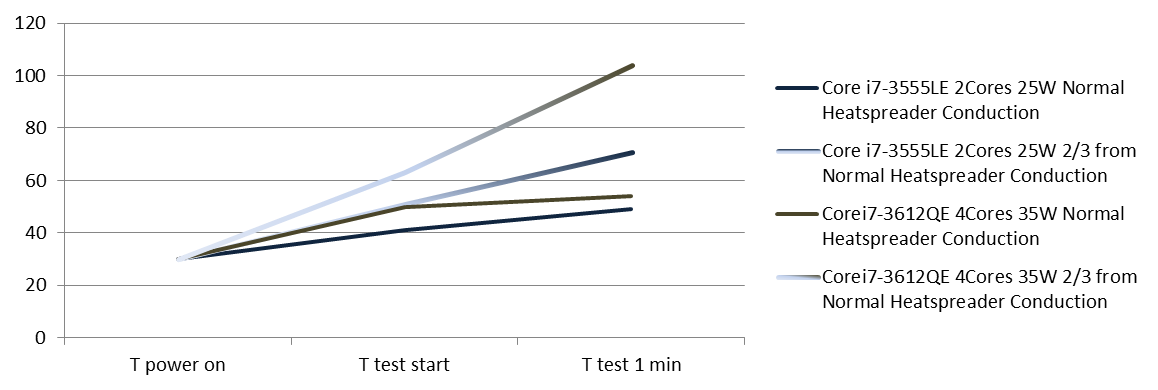

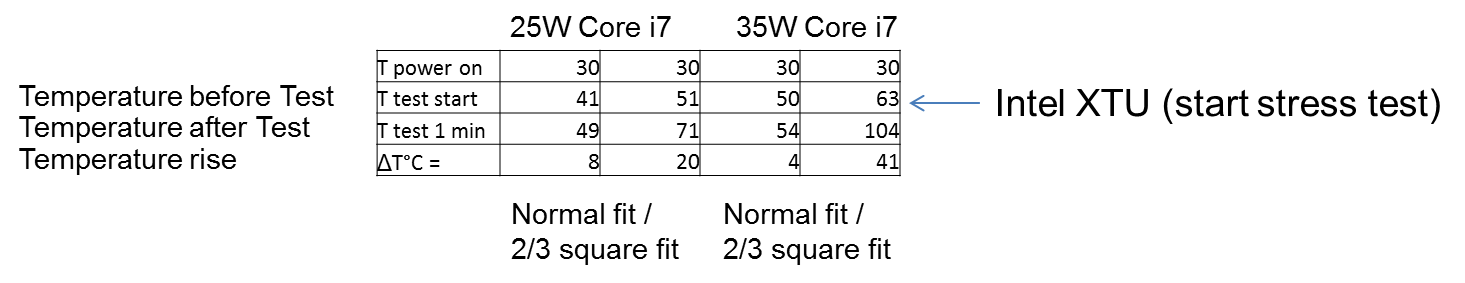

CPC510 HEAT DESSIPATION RESEARCH – HEATSPREADER FIT

What happens if heatspreader fits CPU chip only by 2/3 of its square?

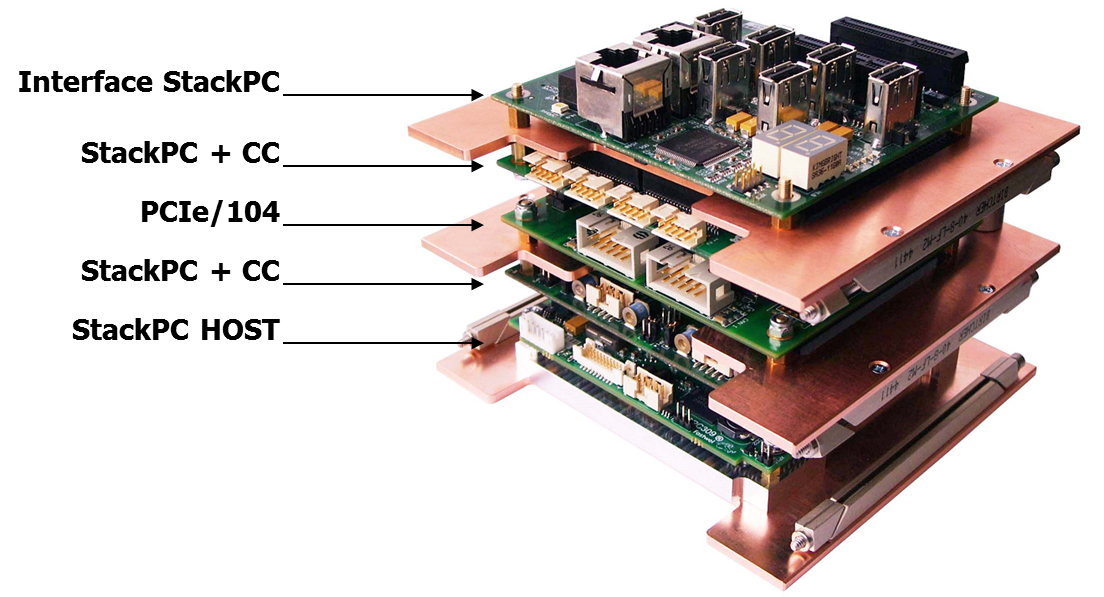

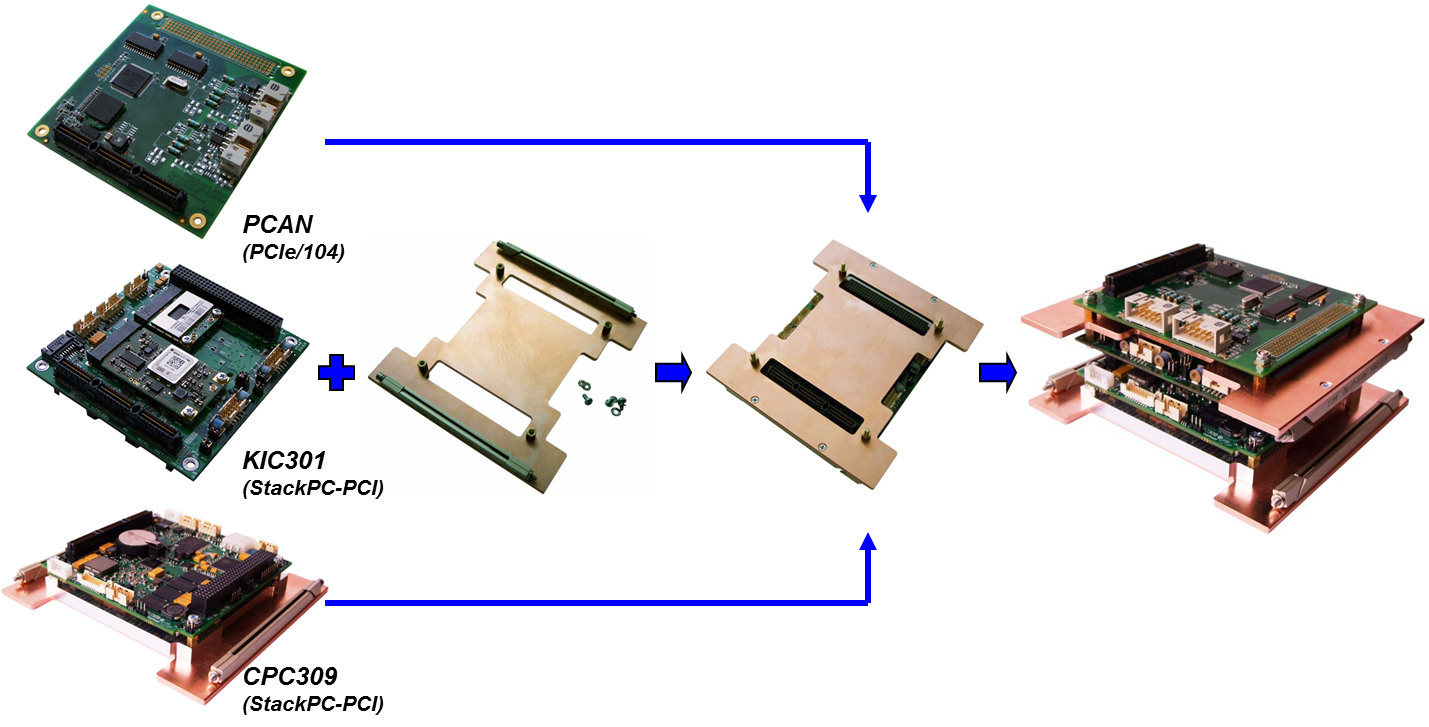

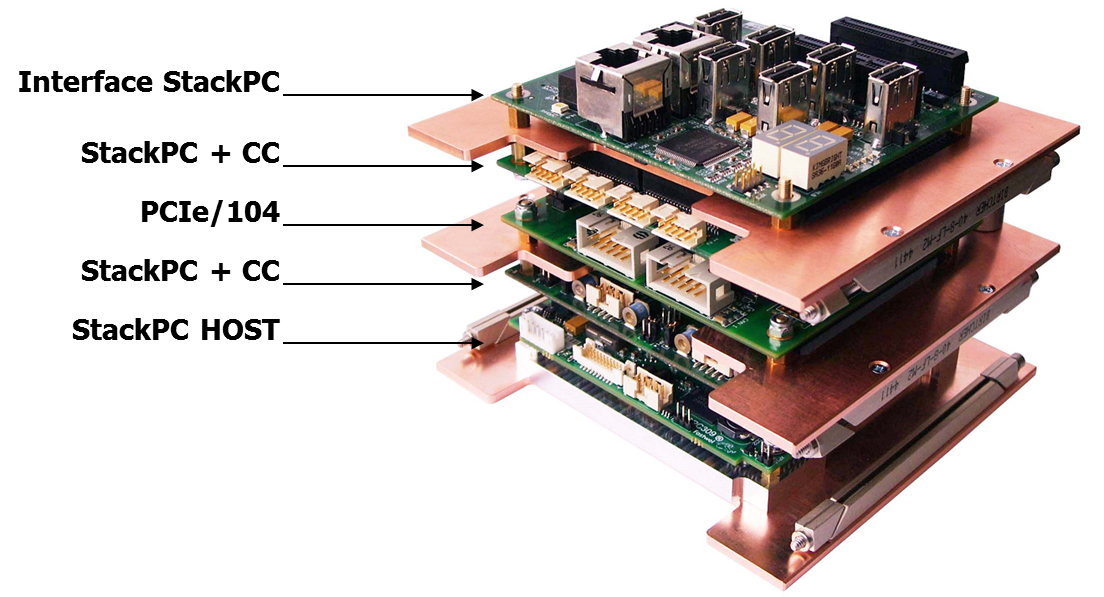

Conduction Cooled Solutions

|

Host CPU and Power modules:

- One way stack only (StackUP)

- Bottom side for Heatspreader

- Bottom side for hot and high components

- Mass production modules adaptation

- Cost effective solution

|

|

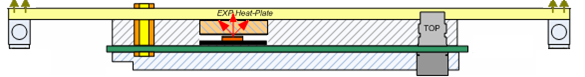

Heatplate provides path for power dissipating along Heatplate to it’s edges and then to enclosure

|

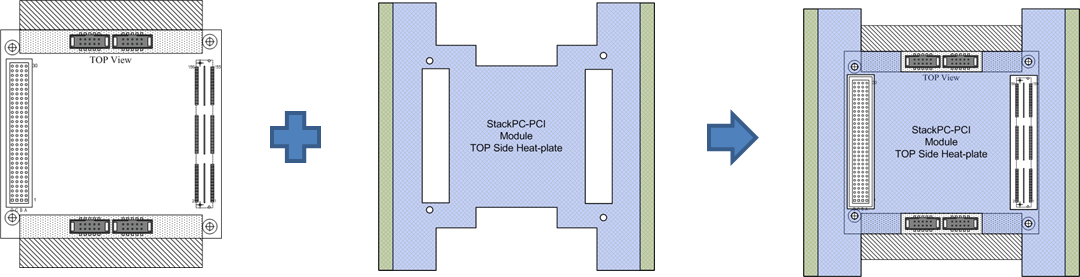

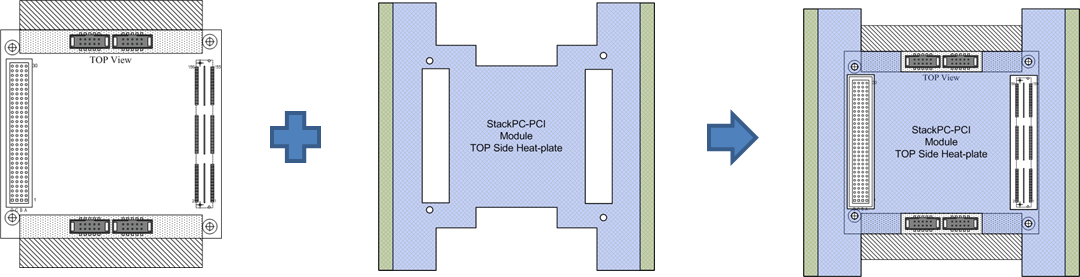

Expansion modules:

- Regular modules dimensions like PC104

- Top side for Heatspreader

- Top side for hot components

- Mass production modules adaptation

- Cost effective solution

|

|

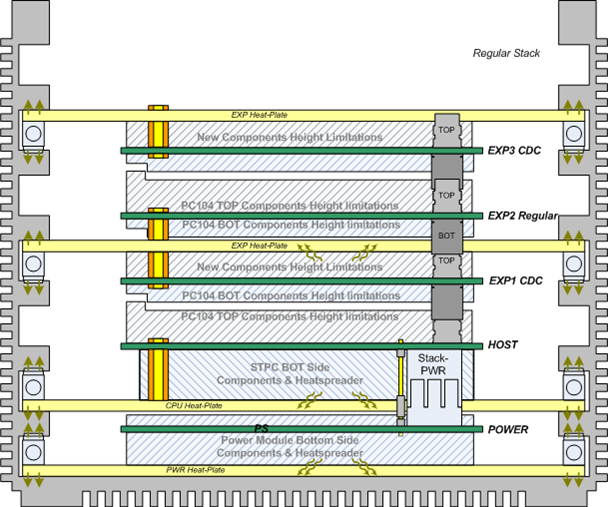

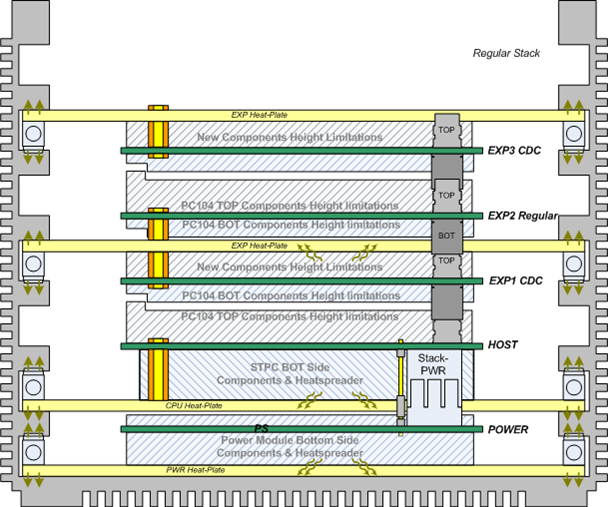

Stack with conduction cooling:

- Regular Stack – any position of stack inside the enclosure

- Regular modules – availability of adding regular modules without heatplates to conduction cooled stack

- Modules with conduction cooling – common approaches for adding heatplates to Power, CPU and Peripheral modules

- Common Heat plates – the same heatplate shape and fix method

- Flexibility – all stackable modules benefits with conduction cooling feature

- Easy to manufacture – just screw wedge locks, easy access to I/O connectors, easy maintenance

|

|

Conduction-Cooled Stack

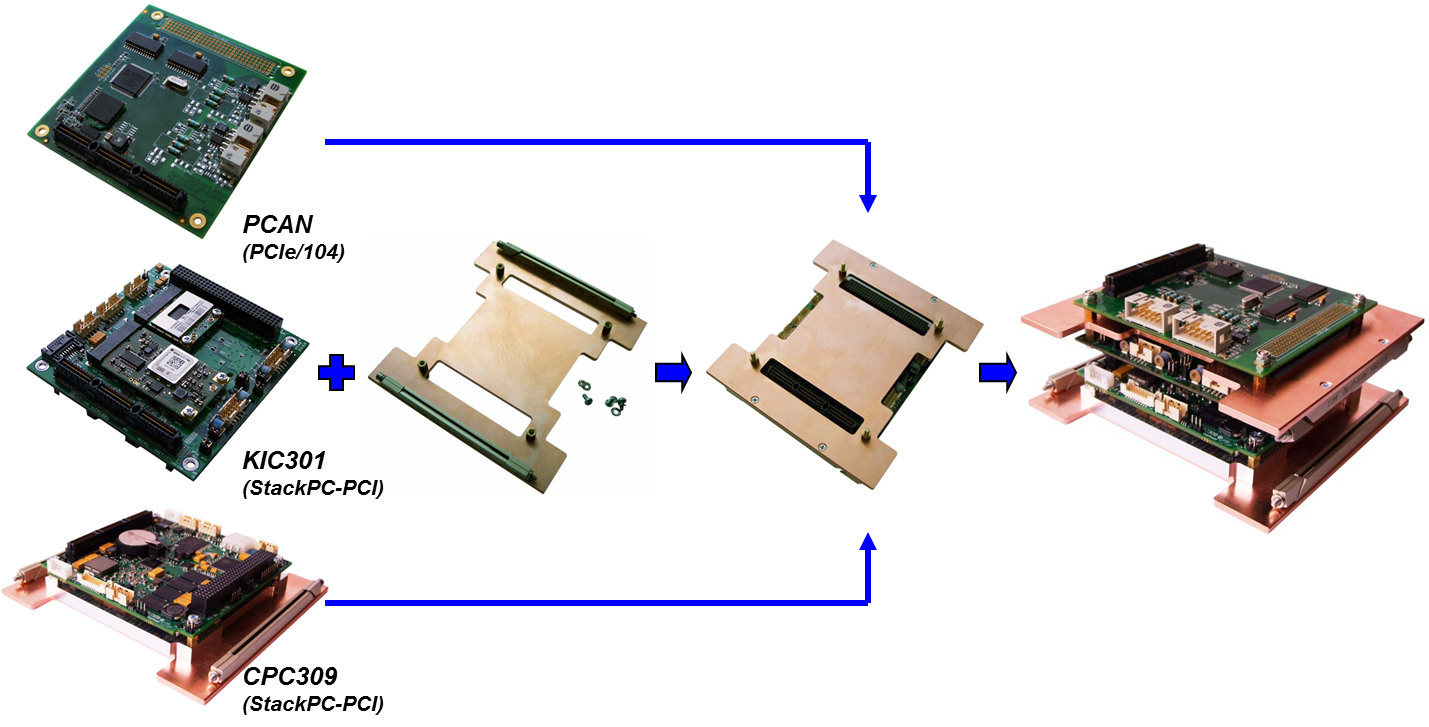

Off-the-shelf modules application for conduction cooling

System example with conduction cooling

Heat Dissipation Version

System example with conduction cooling

System Implementation

|

System example with conduction cooling:

- Regular stack

- Regular modules

- Modules with conduction cooling

- Common heatplates

- Flexibility

- Easy to manufacture

|

|

|

|

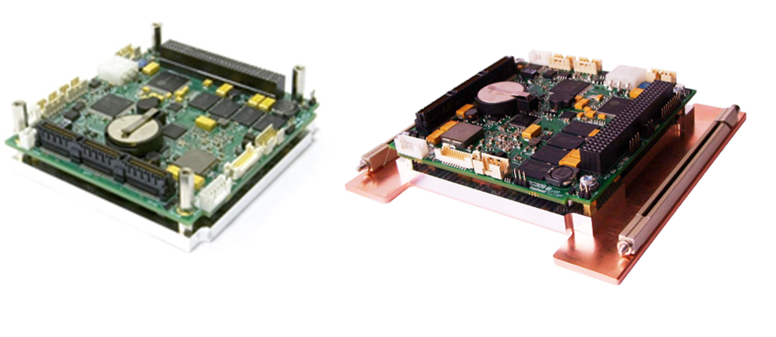

CPC309

|

CPC309+Conduction Cooling

|

MK300

|

.png)