CompactPCI S.0

The CompactPCI family was supplemented in 2011 by the CompactPCI Serial specification. It was developed to renew the data exchange interconnects between modules in CompаctPCI systems and thereby to ensure the solution of modular systems creation tasks in the next 15–20 years.

CompactPCI Serial has five key innovations: new connectors, high-speed interconnects, new layout of connectors on 6U boards, a new power supply layout and conduction cooling technology.

CompactPCI Serial requires only one supply voltage (+12 V) with maximum input power of 60 W for each 3U module and 150 W for 6U modules.

Increase of input power supplied to CompactPCI Serial system controllers enables to install almost any CPUs: both PowerPC and х86 architectures, as well as build computers based on GPUs and FPGA.

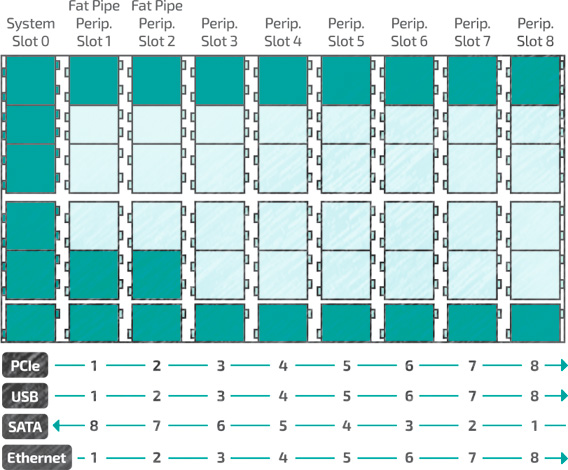

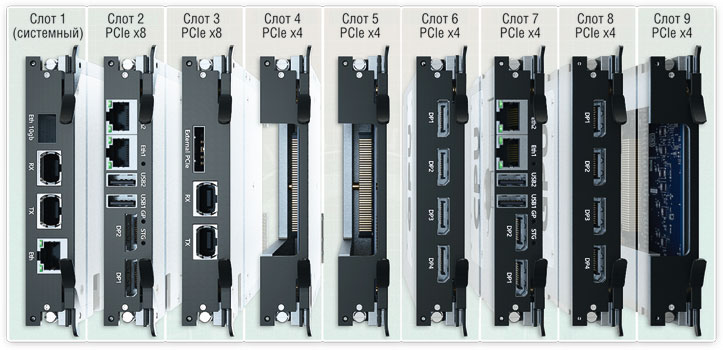

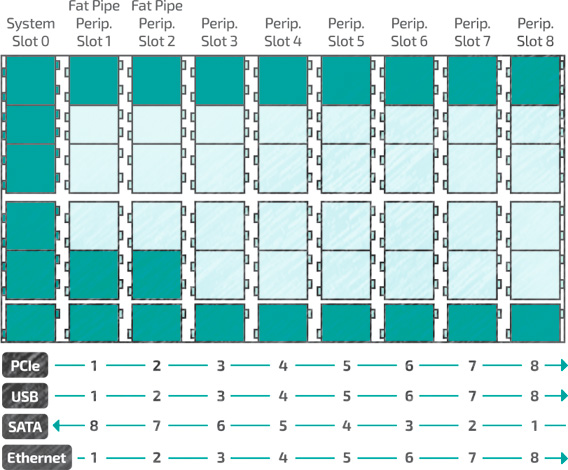

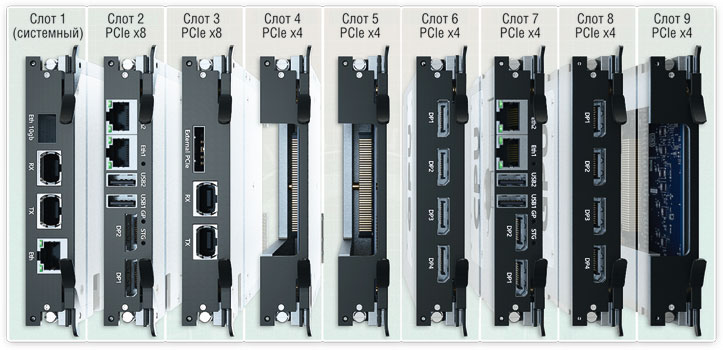

The CompactPCI outlines expressly the four types of interconnects pins (pinout) designation and one I2C check bus on the system controllers and peripheral connectors: 8 PCI-E channels, two of which are х8 and the remaining six are х4; eight Ethernet Base-T channels; eight SAS/SATA channels; eight USB 2.0 or USB 3.0 channels; I2C bus for control and monitoring of the system service parameters.

Connectors

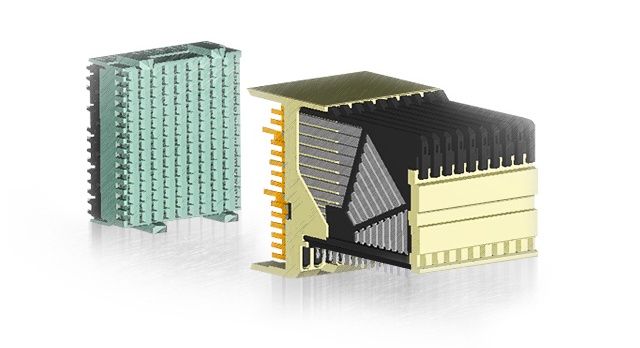

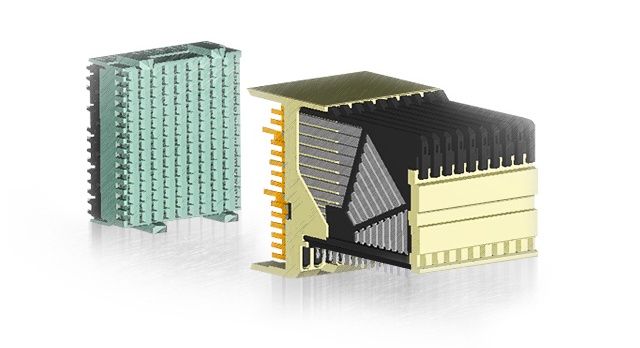

CompactPCI Serial uses new high-density connectors for data transfer both on the side of blade modules and on the side of motherboards.

Testing connectors, e.g. FCI AirMax, showed high quality of signal transmission - up to 12.5 GHz. Structure of the connectors makes it possible to use different sides of the board for their installation, which thereby enables applying mezzanine concept of blade modules creation with connection of mezzanines directly to backplanes.

Interconnects

The CompactPCI outlines expressly the four types of interconnects pins (pinout) designation and one I2C check bus on the system controllers and peripheral connectors: 8 PCI-E channels, two of which are х8 and the remaining six are х4; eight Ethernet Base-T channels; eight SAS/SATA channels; eight USB 2.0 or USB 3.0 channels; I2C bus for control and monitoring of the system service parameters. At the physical level each channel consists of two differential pairs, providing data transfer from source to receiver and reverse. Since all CompactPCI Serial interconnects are serial, the specification describes their topology, namely: PCI-E, SATA and USB have star topology with the system controller (Syst.) as a host, while Ethernet has a full mesh topology or fully connected mesh topology, when each workstation is connected directly to each of the others.

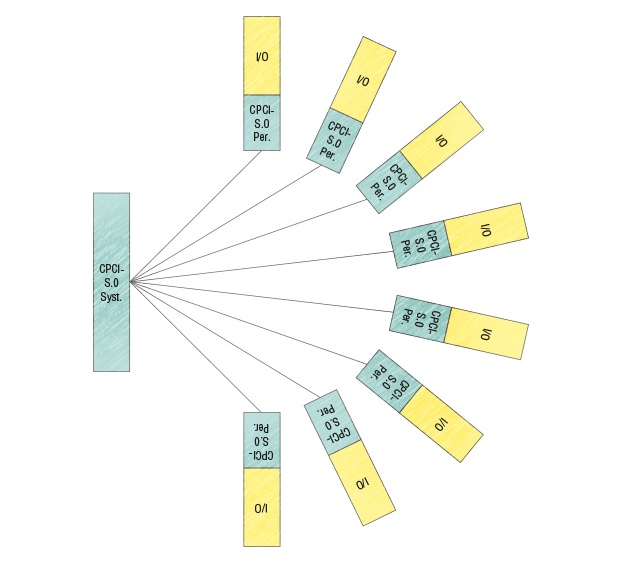

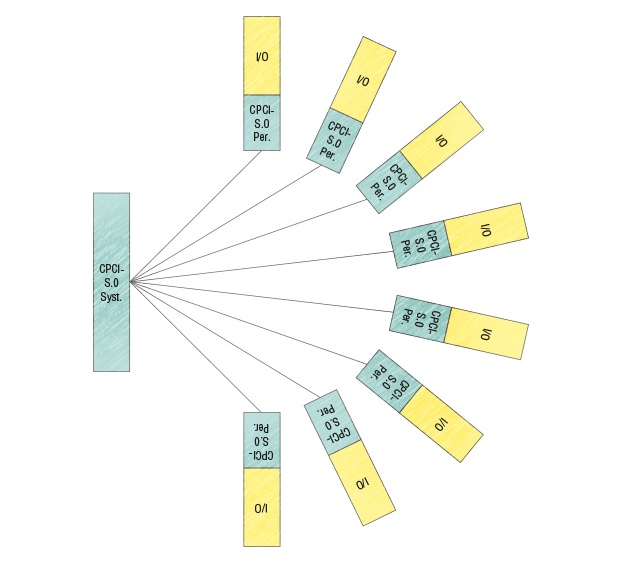

It is important to note that the CompactPCI Serial standard does not impose restrictions on any particular configuration of backplanes, leaving it to customers and manufacturers. Respectively, some systems can be designed for connection of only one application or peripheral (Per.) module, the others – for connecting up to 24 application modules. CompactPCI Serial for 6U modules describes an additional connector on the system controller module, providing two additional Ethernet channels which can be used for ensuring of compatibility with PICMG 2.16, and an additional power supply.

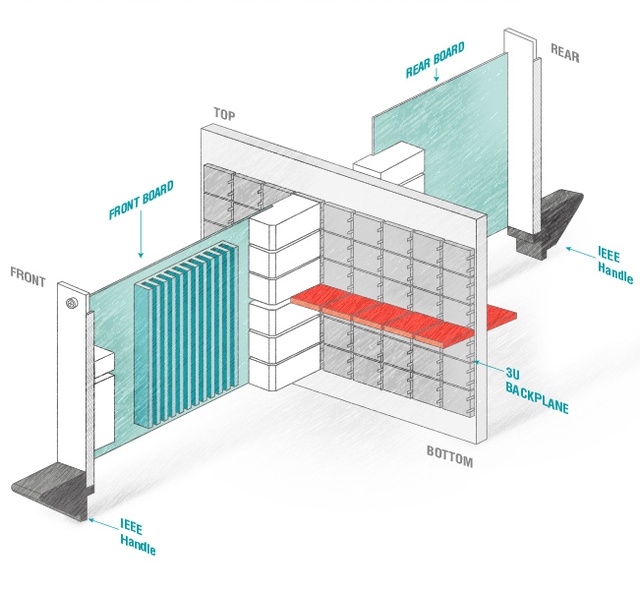

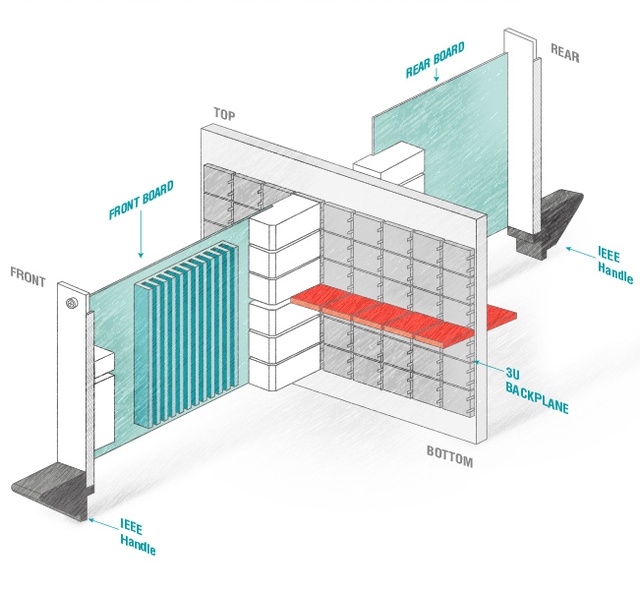

Mechanical structure of blade modules, motherboards

and systems

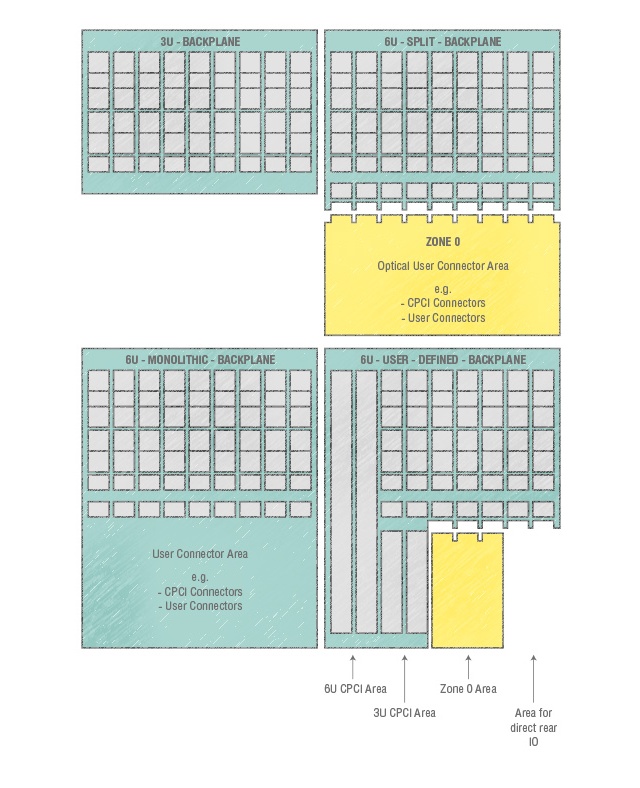

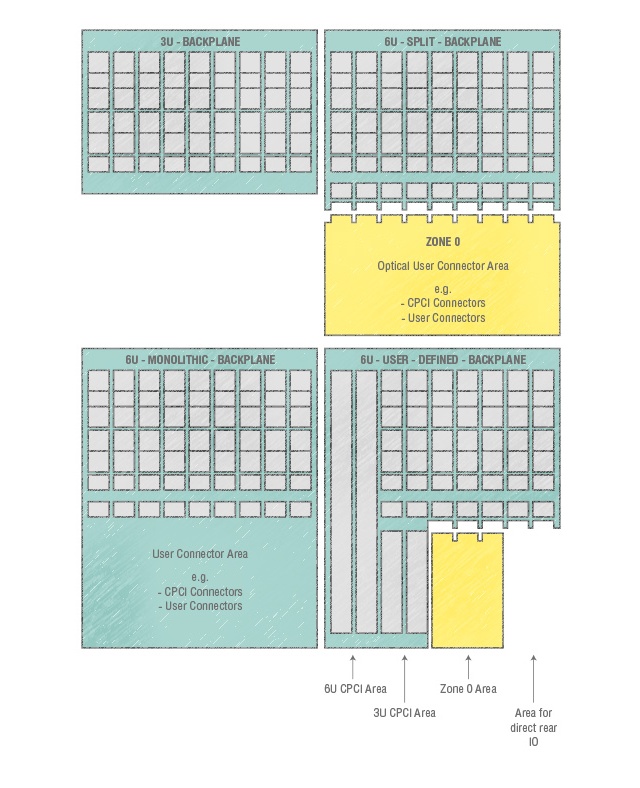

Mechanical structure underwent little changes but resulted in significant consequences for the 6U systems. Thus, all connectors for connection to motherboard are now located in the upper half of the 6U plate, while the lower half remains free and can be used for installation of connectors according to customer’s specification and/or for direct connection to Rear I/O module.

If the organization of the 6U system does not require support of PICMG 2.16 and additional power supply, 3U motherboards can be used in such systems.

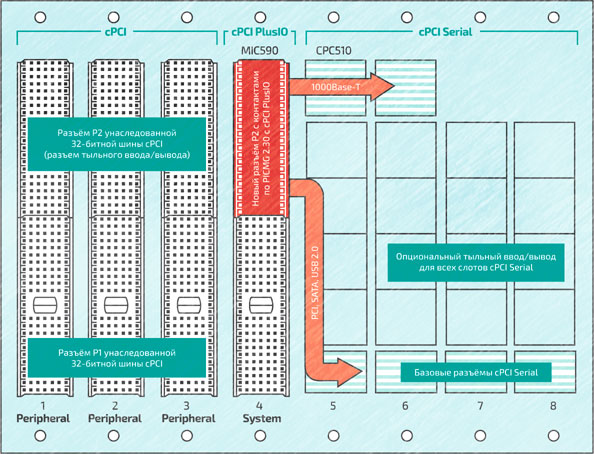

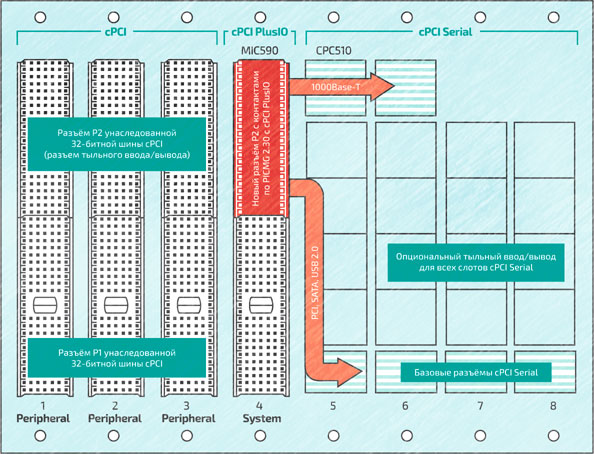

The figure above illustrates different options of implementation of CompactPCI Serial systems (a, b, c) and hybrid systems (d) with monolithic (a, c) and composite (b, d) motherboards. Advantages of such approach consist in the reduction of prices for motherboards – they now became less in size and simpler in manufacturing process, as well as the possibility of supporting inherited (i.e. inherited from previous specifications) interconnects (Ethernet and PCI) and creation of hybrid systems.

In addition to the above-mentioned improvements, there appeared one mechanical element in 3U modules and two mechanical elements in 6U modules, directing and centering the boards when connecting to motherboard, that should simplify the processes of systems assembling and modules replacement for repair.

Fastwel solutions ensure a gradual switchover from standard CompactPCI (PICMG 2.0) or CompactPCI PlusIO (PICMG 2.30) systems to the new Compact PCI Serial (PICMG CPCI-S.0) standard with minimum investments.

Use of the hybrid backplane makes the system very compact and reduces the range of applied components.

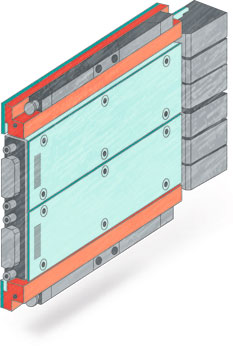

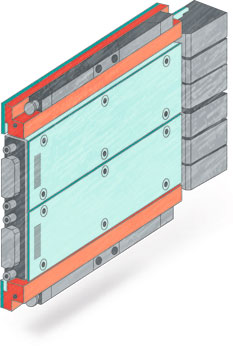

Fastwel offers system developers a simple option of implementation of conduction cooling systems.

This option allows for the standard board packed in a metal holder which is inserted into the system with the 5HP step between modules. This helps to substantially reduce expenses for manufacturing the board with conduction heat removal, and thereby lower its production cost.

Due to the opportunity to change any board in CompactPCI Serial standard with air-cooling into a module with conduction cooling, users can quickly develop conduction heat removal systems. Using CompactPCI Serial boards enables reuse of the accumulated skills, knowledge, tried and tested algorithms when upgrading existing or developing new systems.

Fastwel solutions ensure possibility of creating multiprocessor and heterogeneous systems.

Solving current computational problems of special-purpose systems is associated with the processing high-intensity streams of various data types – a signal information, encrypted traffic, data from multiple sensors, streaming video etc. In this case, for maximum efficient processing of structure and heterogeneous information it is reasonable to use processing computers of various architecture types (FPGA, x86, Elbrus, graphics processors), best suited for particular data type.

New power supply layout

New connectors also allowed to improve the power supply system. Specifically, CompactPCI Serial requires only one supply voltage (+12 V) with maximum input power of 79.8 W for each 3U module and 171 W for 6U module, required for provision of power supply to 8HP or 12HP high-productive modules or for provision of power supply to modules with conduction or fluid cooling.

Besides, CompactPCI Serial provides the system controller with a possibility to control the power supply, for example, upon occurrence of this or that event (wake on LAN or wake on modem). Therefore, the functions implemented in all modern processors and chipsets can be used for creation of an embedded system.

Conduction cooling

The CompactPCI Serial specification offers to systems developers a simple option of implementation of the systems with conductive cooling. This option assumes packing of the standard board in a metal holder which is inserted into the system with the 5HP step between modules.

.png)