07.04.2020

By Nikolay Sergienko

The FASTWEL trademark is well known in the Russian industrial electronics market. A number of embedded solutions and industrial controllers have been manufactured under FASTWEL trademark for several decades. Resistance to environmental effects: temperature fluctuations in the range from – 40 °C to + 80 ° C, high humidity, shocks and vibrations, electromagnetic radiation, etc. is one of the key characteristics of FASTWEL equipment. This article contains new arrivals in the FASTWEL range of embedded solutions.

CompactPCI Standard Boards

The CompactPCI standard is well known to many industries where there is a demand for processing large amounts of information in real time. Solving such problems requires a powerful processing platform and a large number of data transmission channels with high bandwidth. The CompactPCI systems enable to place the required number of processor and peripheral modules within a single 19” Eurocard frame, and data exchange between such modules is carried out over a single bus with high bandwidth.

FASTWEL manufactures a range of devices in the CompactPCI Serial format, many of which have truly gained popularity and are currently used in a wide variety of projects. Today, this product line was expanded with new devices.

The CPC514 and CPC516 CPU modules stand out from the CompactPCI Serial 3U range. The first of them is based on the “Elbrus-4S” processor (the processor was developed by the MCST company), the second one is built on “Baikal – T” processor. The both boards will be appealing primarily to those customers who want to try alternative reliable technologies and get the high level of data protection.

CPC514 CPU Module

The CPC514 module, based on the Russian-made Elbrus-4S processor (Fig. 1), is manufactured in two versions: with forced and conduction cooling. The module is designed for use in real-time systems, production control and other systems for data acquisition and processing that are used under harsh conditions and require reliability, information security and flexibility in supporting various expansion interfaces.

The CPC514 module, based on the Russian-made Elbrus-4S processor (Fig. 1), is manufactured in two versions: with forced and conduction cooling. The module is designed for use in real-time systems, production control and other systems for data acquisition and processing that are used under harsh conditions and require reliability, information security and flexibility in supporting various expansion interfaces.

Four processor cores, operating at a frequency of 600 MHz, 8 GB of soldered DDR3 RAM, soldered SSD-drive with 16 GB combined with three SATA interfaces for installation of additional storage devices, 3x 10/100/1000 Gigabit Ethernet ports, 9x USB 2.0 ports, integrated video interface with a resolution of 1600×1200 and AC’97 audio codec make the new module to be richly equipped and ensure a wide range of applications.

CPC514 provides efficient solution to the problems of industrial automation systems, data acquisition and processing in the Oil & Gas sector, railway and automobile transport, nuclear power and other industries that require exclusive Approach developments. Support for the “Neutrino-E” protected real-time operating system makes it possible to use the new module in systems for which compliance with the requirements for the third class of information protection against unauthorized access, with two levels of control of the absence of undocumented features, with two classes of security for network firewalls, are crucial.

CPC516 CPU Module

The CPC516 module (Fig. 2) built on “Baikal-T” is a highly integrated and energy-efficient solution based on the MIPS32 platform.

The CPC516 module (Fig. 2) built on “Baikal-T” is a highly integrated and energy-efficient solution based on the MIPS32 platform.

The module is equipped with a dual-core “Baikal-T” processor with a clock speed of 1.2 GHz, 4 GB DDR3-1600 RAM soldered onboard, 8 GB SSD with 1.5 Gb/sec. Gen I, 3 Gb/sec. Gen II and 6 Gb/sec.Gen III. DisplayPort is used as video output, which can display an image with a resolution of 1920×1080 at a frequency of 50 Hz. Another obvious advantage of this module is not only the availability of two Ethernet ports with a data transfer rate of 1 Gb/sec, but also a 10 GbE port with 1000V individual galvanic isolation of each port. In addition, the board has two RS-232 COM ports, USB 1.0 and 2.0 with data transfer rate up to 480 Mb/sec and a hardware watchdog timer with an interval configurable within the range from 1 µs to 10 minutes.

The new product is perfect for use in real-time systems, production control, data acquisition and processing for harsh operating conditions and mission-critical applications.

CPC518 CPU Module

Another new CompactPCI Serial 3U CPU module is CPC518 (Fig. 3), which is built on Intel Xeon-D processor family and is made in five versions. Among them are the versions with Intel Xeon D-1519, Xeon D-1539 and Xeon D-1559, the amount of RAM varies from 16 to 32 GB. Depending on the design, the operating temperature range also changes: the user can choose a device that operates in the temperature range from 0 to +70°C or from -40 to +85°C.

Another new CompactPCI Serial 3U CPU module is CPC518 (Fig. 3), which is built on Intel Xeon-D processor family and is made in five versions. Among them are the versions with Intel Xeon D-1519, Xeon D-1539 and Xeon D-1559, the amount of RAM varies from 16 to 32 GB. Depending on the design, the operating temperature range also changes: the user can choose a device that operates in the temperature range from 0 to +70°C or from -40 to +85°C.

As pertains to the processor modules focused on the server-class tasks, the CPC518 module is equipped with 2x 10 GbE ports (2x SPF+ channels, support of the Fibre Channel modules), 1x GbE port, 4x USB 2.0 and 4x USB 3.0 ports, 6-channel SATA interface with RAID 0, 1, 5, 10 support and running under Linux 3.19, QNX 6.5.0, Microsoft Windows Embedded Standard 7 or 10. The module is also equipped with a DisplayPort interface for output of a video stream with the resolution up to 1920×1440 and a frequency of 60 Hz.

The main application areas of CPC518 include modular server solutions in the CompactPCI format, data processing centers, data storage systems, and resource-intensive computing in a variety of industries that require high power and high scalability of computer systems.

CPC520 CPU Module

At the end of 2019, the first samples of the CPC520 Module, which replaced another popular model – CPC508, were tested. The new module is primarily aimed at those who already use CompactPCI I/O processor modules (PICMG 2.30) with their solutions.

At the end of 2019, the first samples of the CPC520 Module, which replaced another popular model – CPC508, were tested. The new module is primarily aimed at those who already use CompactPCI I/O processor modules (PICMG 2.30) with their solutions.

This is the first module based on the AMD Ryzen Embedded processor, which includes 8x GPU cores along with 4x processor cores. The front panel of the module displays 2x DisplayPort interfaces for connecting displays with a 4K resolution. CPC520 with 8 GB DD4 RAM, 2x GbE ports with data transfer rates of up to 1 Gb/sec, 2x USB 3.0 ports and a 16 GB SSD are part of this modern computer. The module would be a perfect tool for creating medium and large real-time process control systems and machine vision systems. In addition to industrial automation, CPC520-based solutions can be used in medical imaging systems, display of advertising and informational content in shopping centers, train stations, and airports.

KIC502 and KIC504 Extension Modules

Attention should be given to the new KIC502 (Fig. 4) and KIC504 (Fig. 5) interface modules, which have recently appeared in the CompactPCI product line. The devices are designed for ensuring the CompactPCI Serial format cards to work together with the CompactPCI cards of previous generation.

Attention should be given to the new KIC502 (Fig. 4) and KIC504 (Fig. 5) interface modules, which have recently appeared in the CompactPCI product line. The devices are designed for ensuring the CompactPCI Serial format cards to work together with the CompactPCI cards of previous generation.

The first version of the CPCI specification appeared as far back as 1999, and since then many various peripheral modules have been released in this format. They are still used in automated control systems where high rate of data exchange is not required. When creating the up-to-date automation tools, there is a need to accept and process large data flows and in this case the CompactPCI Serial format is chosen.

In order to reduce the cost of purchasing new peripheral modules, you can use long-familiar reliable and proven CPCI devices. The KIC502 and KIC504 adapters are designed to connect them to the new CompactPCI Serial system. Moreover, if the number of CPCI-S peripheral modules does not exceed 3 or the number of CompactPCI modules is less than 7, then the KIC502 and KIC504 interface boards can be placed in the same frame. In this case, a mezzanine connection is used (Fig. 6). If the new and old generation boards need to be placed in different frames, a PCI Express cable connection can be applied. In this case, several frames with CompactPCI modules of the previous generation can be connected to the CompactPCI Serial system.

In order to reduce the cost of purchasing new peripheral modules, you can use long-familiar reliable and proven CPCI devices. The KIC502 and KIC504 adapters are designed to connect them to the new CompactPCI Serial system. Moreover, if the number of CPCI-S peripheral modules does not exceed 3 or the number of CompactPCI modules is less than 7, then the KIC502 and KIC504 interface boards can be placed in the same frame. In this case, a mezzanine connection is used (Fig. 6). If the new and old generation boards need to be placed in different frames, a PCI Express cable connection can be applied. In this case, several frames with CompactPCI modules of the previous generation can be connected to the CompactPCI Serial system.

MicroPC Boards

The first MicroPC solutions appeared more than 20 years ago and have proven themselves in the segment of industrial computers due to a number of distinctive features, including configuration flexibility, ease of installation and setup, excellent computing capabilities, convenient and efficient heatsink, a wide range of peripherals. The design of industrial MicroPCs is somewhat similar to the CompactPCI format. They are also equipped with a common basket (crate) of the 19” Eurocard format with a backplane, where CPU modules, as well as I/O boards, interface boards and other peripherals, are housed. In the late 1990s and early 2000s, the MicroPC standard gained a niche for automated control systems, where it has been successfully used to this day.

FASTWEL manufactures a number of devices in this format, continuing to support the previous versions and offering modern, significantly improved products. The boards built on the Geode LX800 processor are currently replaced by the new ones based on the Vortex86DX processor.

CPC109 and CPC152 CPU Modules

CPC109 and CPC152 CPU Modules

The CPC109 module (Fig. 7) was released in order to replace the popular CPC107 model, which became widely used in industrial automation applications. Physical interfaces of the new module and of its predecessor are entirely similar. Therefore, when installing CPC109 instead of CPC107, the user does not have to change the peripherals, just make changes to the software.

The new board is equipped with the Vortex86DX™ CPU with a clock speed of 600 MHz, 256 MB DDR2 SDRAM, integrated SSD with 2 GB, ports for HDD connection, 100 GbE, 3x USB, 6x COM-ports RS-232 and RS-422/485, as well as a universal digital port with 72 CMOS/TTL lines, GPIO port for 8x lines, 8x isolated analog inputs and 2x outputs. The board is also equipped with two watchdog timers built into the processor with a response interval from 30.5 µs to 512 s and one integrated into the power supervisor with a response interval of 1.6 s.

The list of the supported operating systems includes MS-DOS®6.22, FreeDOS, Linux 2.6, QNX 6.4x, and Windows CE 5.0. The availability of such richly equipped modifications opens up a wide range of applications for this module related to data acquisition and management. The module is primarily designed for building highly reliable automated control systems, dispatching and telemetry systems.

The list of the supported operating systems includes MS-DOS®6.22, FreeDOS, Linux 2.6, QNX 6.4x, and Windows CE 5.0. The availability of such richly equipped modifications opens up a wide range of applications for this module related to data acquisition and management. The module is primarily designed for building highly reliable automated control systems, dispatching and telemetry systems.

CPC152 board (Fig. 8) is also built on the basis of Vortex86DX™ CPU with a clock speed of 600 MHz, but has a number of variations from the CPC109. First is the availability of the multimedia: graphics card with the ports connecting an RGB monitor with a resolution of up to 1920×1440, LCD panels (TFT or DSTN) with a resolution of up to 1920×1440, display through a separate VGA port (IDC2-10 socket) and also with the possibility of display connection via a standard DSUB15F connector using KIB98102 interface card; sound card's line input and output as well as microphone input. Secondly is that the model is equipped with a digital accelerometer, barometer, gyroscope and temperature sensor. From the I/O ports, there are GPIO, 4x USB, 2x RS-232 and RS-422/485, a universal parallel LPT port. All elements are soldered to the board, which makes it resistant to vibration. CPC152 can be successfully used as an onboard computer, as well as in process control systems under harsh operating conditions.

PC/104 Boards

PC/104 Boards

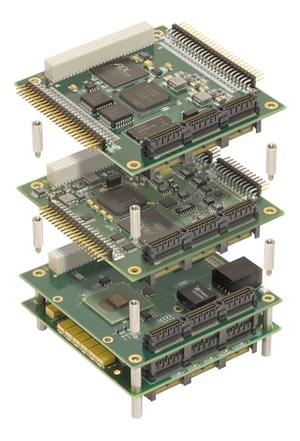

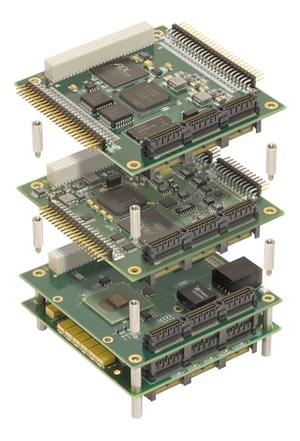

PC/104 computers are widely used in areas with a need for getting maximum performance. The computers have small enclosures and minimum power consumption. These solutions use special-purpose processors with low power consumption that do not require forced cooling. Configuration flexibility is ensured by a wide range of PC/104 boards: CPU, communication, navigation, digital and analog I/O, power supply boards, etc., which are assembled into a single and unified “sandwich” (Fig. 9). Compact size of the modules also ensure high mechanical strength, while reliable screw fasteners add additional rigidity. The PC/104 solutions can operate under constant vibration conditions and are able to withstand impact loads, which makes them suitable for those tasks where such operating conditions are common. Data exchange and power supply are carried out through the harmonized connectors via ISA bus. At the same time, the PC/104 Plus format got support of the PCI bus, and the StackPC format got support of the faster PCIe bus.

Capacity of the computers, their compact size, lack of moving parts, and resistance to shocks and vibrations make the PC/104 solutions and their variations a must-have equipment in the onboard data acquisition and control systems for ground and air transport, automation of mission-critical facilities, as well as in special-purpose applications.

CPC313 CPU Module

Special consideration deserves the CPC313 CPU Module (Fig. 10) implemented in StackPC format, which is based on the Russian-made “Baikal-T1” CPU. This processor has 2x cores running at a frequency of 1.2 GHz, an integrated graphics card, capable of delivering Full HD 1920×1080 images, and is also equipped with 2x GbE ports with a rate of 1 Gb/sec and one 10 GbE port. Being equipped like this, the CPU consumes only 5 W and is perfect for embedded solutions with conduction cooling.

Special consideration deserves the CPC313 CPU Module (Fig. 10) implemented in StackPC format, which is based on the Russian-made “Baikal-T1” CPU. This processor has 2x cores running at a frequency of 1.2 GHz, an integrated graphics card, capable of delivering Full HD 1920×1080 images, and is also equipped with 2x GbE ports with a rate of 1 Gb/sec and one 10 GbE port. Being equipped like this, the CPU consumes only 5 W and is perfect for embedded solutions with conduction cooling.

The CPC313 module is fitted with 4 GB RAM, 8 GB SSD, 2x USB 2.0 and 2x RS-232 ports, PCI/104 bus connector, a real-time clock with a lithium battery, and a hardware watchdog timer. Based on this module, the MK150-02 modular computer was released in 2019 (Fig. 11). This computer supports FBUS and is compatible with the I/O modules of the well-known Russian-made FASTWEL I/O controller.

The CPC313 module is fitted with 4 GB RAM, 8 GB SSD, 2x USB 2.0 and 2x RS-232 ports, PCI/104 bus connector, a real-time clock with a lithium battery, and a hardware watchdog timer. Based on this module, the MK150-02 modular computer was released in 2019 (Fig. 11). This computer supports FBUS and is compatible with the I/O modules of the well-known Russian-made FASTWEL I/O controller.

Therefore, the CPC313 module is a new highly integrated and energy-efficient solution designed for use in real-time systems, production control, data acquisition and processing for harsh operating conditions and mission-critical applications. The module entered serial production at the end of 2019.

CPC310 CPU Module

CPC310 (Fig. 12) is another module implemented in the PC/104 form-factor based on the Intel Atom CPU of the E38xx series. Among the module versions are those equipped with a single-core and dual-core CPUs, 2 / 4 GB RAM, and 4 / 8 GB of NAND Flash. Support of external drives via SATA and CFast connectors is also ensured. The module’s video controller enables you to display images with a resolution of up to 2560×1600via the VGA output and at a frequency of 60 Hz, and it also has 2x LVDS ports which make it possible to get images with a resolution of 1600×1200, at a frequency of 60 Hz and a bit depth up to 24 bits. An integrated audio chip supports HD Audio codec, has a linear input and output, and a microphone input. The module is also equipped with 2x GbE ports, 2x COM-ports RS-232 and 2x RS-422/485 ports, a parallel LPT port, an 8x channel digital I/O port, keyboard and mouse ports.

CPC310 (Fig. 12) is another module implemented in the PC/104 form-factor based on the Intel Atom CPU of the E38xx series. Among the module versions are those equipped with a single-core and dual-core CPUs, 2 / 4 GB RAM, and 4 / 8 GB of NAND Flash. Support of external drives via SATA and CFast connectors is also ensured. The module’s video controller enables you to display images with a resolution of up to 2560×1600via the VGA output and at a frequency of 60 Hz, and it also has 2x LVDS ports which make it possible to get images with a resolution of 1600×1200, at a frequency of 60 Hz and a bit depth up to 24 bits. An integrated audio chip supports HD Audio codec, has a linear input and output, and a microphone input. The module is also equipped with 2x GbE ports, 2x COM-ports RS-232 and 2x RS-422/485 ports, a parallel LPT port, an 8x channel digital I/O port, keyboard and mouse ports.

The module is a universal single-board computer and is designed for solving a broad range of tasks, including mission-critical applications. It should be noted that the CPC310 module will be available for order until 2030.

Conclusion

FASTWEL provides for testing all the devices described in this article. In order to get any of the modules mentioned here, which will be used as the basis for the development of the management system you need, just submit a brief description of your project to [email protected]. To do so, please use the company’s website that contains all technical documentation for FASTWEL products, you can also use the website for downloading the latest releases of software and contact our experts for technical assistance.

In the next issue, we will present you the latest developments of the FASTWEL I/O industrial controllers.

.png)

The

The  The

The  Another new CompactPCI Serial 3U CPU module is

Another new CompactPCI Serial 3U CPU module is  At the end of 2019, the first samples of the

At the end of 2019, the first samples of the  Attention should be given to the new

Attention should be given to the new  In order to reduce the cost of purchasing new peripheral modules, you can use long-familiar reliable and proven CPCI devices. The KIC502 and KIC504 adapters are designed to connect them to the new CompactPCI Serial system. Moreover, if the number of CPCI-S peripheral modules does not exceed 3 or the number of CompactPCI modules is less than 7, then the KIC502 and KIC504 interface boards can be placed in the same frame. In this case, a mezzanine connection is used (Fig. 6). If the new and old generation boards need to be placed in different frames, a PCI Express cable connection can be applied. In this case, several frames with CompactPCI modules of the previous generation can be connected to the CompactPCI Serial system.

In order to reduce the cost of purchasing new peripheral modules, you can use long-familiar reliable and proven CPCI devices. The KIC502 and KIC504 adapters are designed to connect them to the new CompactPCI Serial system. Moreover, if the number of CPCI-S peripheral modules does not exceed 3 or the number of CompactPCI modules is less than 7, then the KIC502 and KIC504 interface boards can be placed in the same frame. In this case, a mezzanine connection is used (Fig. 6). If the new and old generation boards need to be placed in different frames, a PCI Express cable connection can be applied. In this case, several frames with CompactPCI modules of the previous generation can be connected to the CompactPCI Serial system.

CPC109 and CPC152 CPU Modules

CPC109 and CPC152 CPU Modules

The list of the supported operating systems includes MS-DOS®6.22, FreeDOS, Linux 2.6, QNX 6.4x, and Windows CE 5.0. The availability of such richly equipped modifications opens up a wide range of applications for this module related to data acquisition and management. The module is primarily designed for building highly reliable automated control systems, dispatching and telemetry systems.

The list of the supported operating systems includes MS-DOS®6.22, FreeDOS, Linux 2.6, QNX 6.4x, and Windows CE 5.0. The availability of such richly equipped modifications opens up a wide range of applications for this module related to data acquisition and management. The module is primarily designed for building highly reliable automated control systems, dispatching and telemetry systems.

PC/104 Boards

PC/104 Boards

Special consideration deserves the

Special consideration deserves the  The CPC313 module is fitted with 4 GB RAM, 8 GB SSD, 2x USB 2.0 and 2x RS-232 ports, PCI/104 bus connector, a real-time clock with a lithium battery, and a hardware watchdog timer. Based on this module, the MK150-02 modular computer was released in 2019 (Fig. 11). This computer supports FBUS and is compatible with the I/O modules of the well-known Russian-made FASTWEL I/O controller.

The CPC313 module is fitted with 4 GB RAM, 8 GB SSD, 2x USB 2.0 and 2x RS-232 ports, PCI/104 bus connector, a real-time clock with a lithium battery, and a hardware watchdog timer. Based on this module, the MK150-02 modular computer was released in 2019 (Fig. 11). This computer supports FBUS and is compatible with the I/O modules of the well-known Russian-made FASTWEL I/O controller.